The Janus 450 Engine: Part Two

September 28, 2021

Share this post

The Janus 450 Engine: Part Two

With the launch of the new Halcyon 450, I thought I would take a minute to discuss the heartbeat of the new machine: the engine. This is the second installment of a two part post that looks at our reasons for selecting the engine, its storied history, and journey of integrating it into a new Halcyon model. To catch the first half, check out Part One.

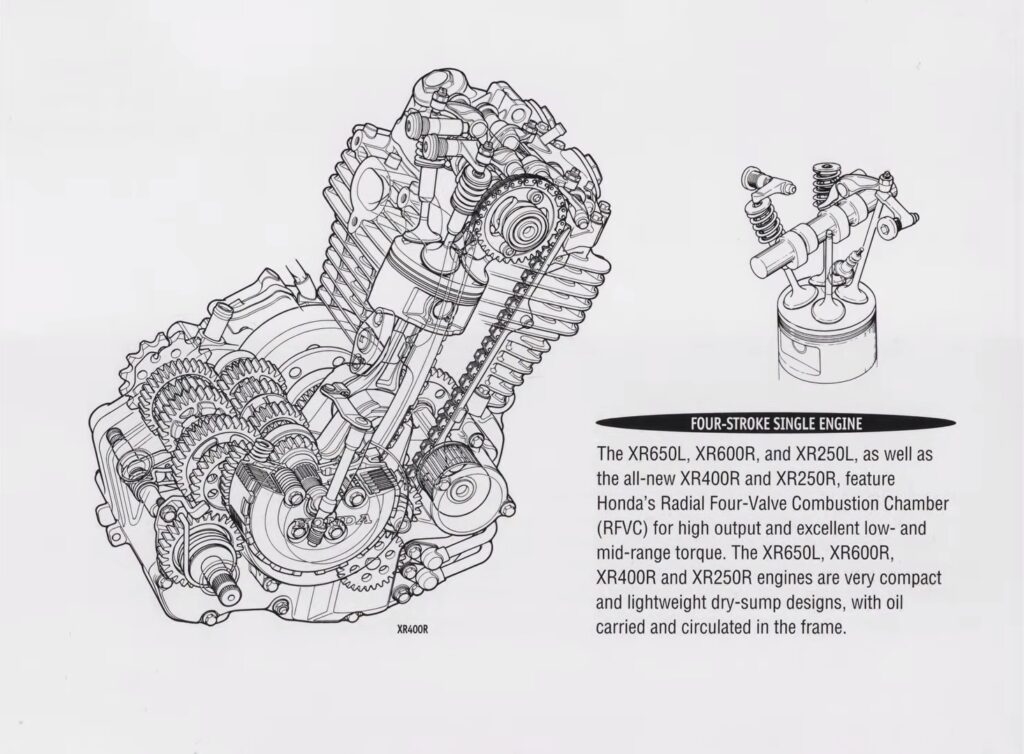

The Honda XR: A Timeless Enduro

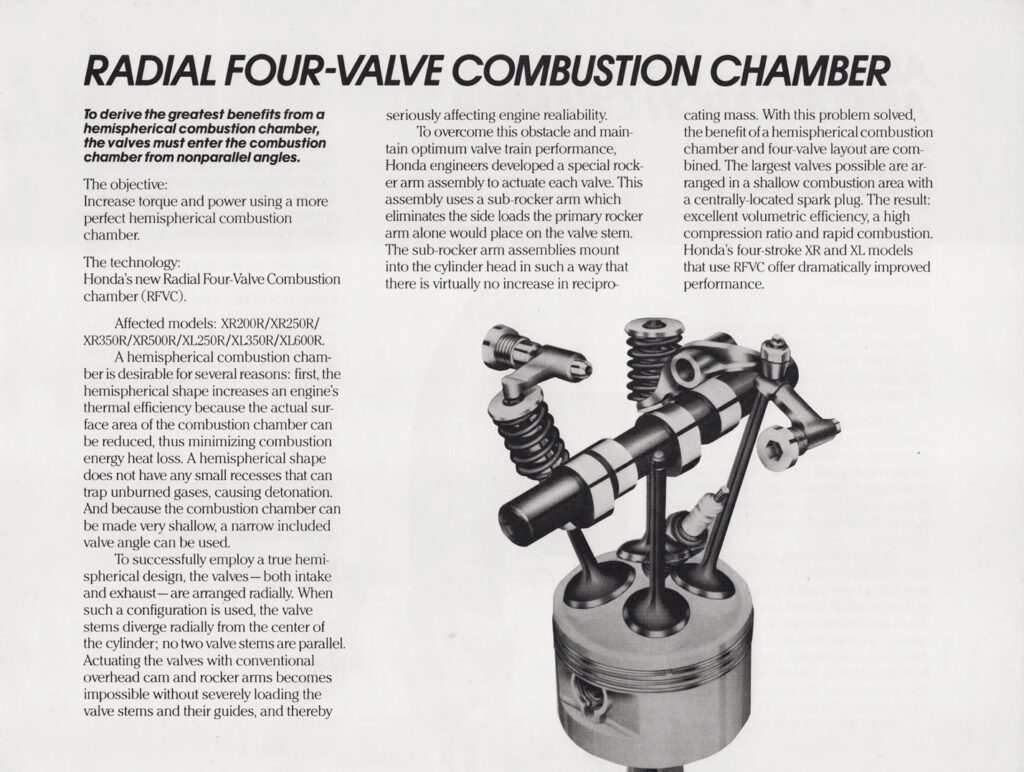

The Honda XR line of enduro motorcycles was originally introduced in 1979, but it wasn’t until 1983 that they came out with the XR350 and XR500 which featured Honda’s brand new RFVC or Radial Four Valve Chamber. This was a shallow “hemi”or hemispherical cylinder head design where each of the four valves are located radially around the combustion chamber, each on its own plane. This is opposed to the alternate four valve “pent-roof” design in which the paired intake and exhaust valves each share a plane on either side of what becomes a tent-shaped combustion chamber. The hemispherical combustion chamber maximized available valve area for larger valves than the pent-roof design, which in turn allowed for higher rpms and a quicker, more even combustion at higher compression ratios.

The XR line was an immediate success in the enduro market and hit a high point with the 1985 XR350 which is still considered one of the best enduro motorcycles ever made, largely due to the unbreakable reliability of the engine and its rewarding performance for its relatively low 25 horsepower. While never designed to be as competitive as Honda’s motocross CR line, the XR’s did achieve success in enduro and even motocross events, including victories in the Paris-Dakar Rally in the early 80’s with the XR500R, although it was more at home as a fun and reliable trail bike.

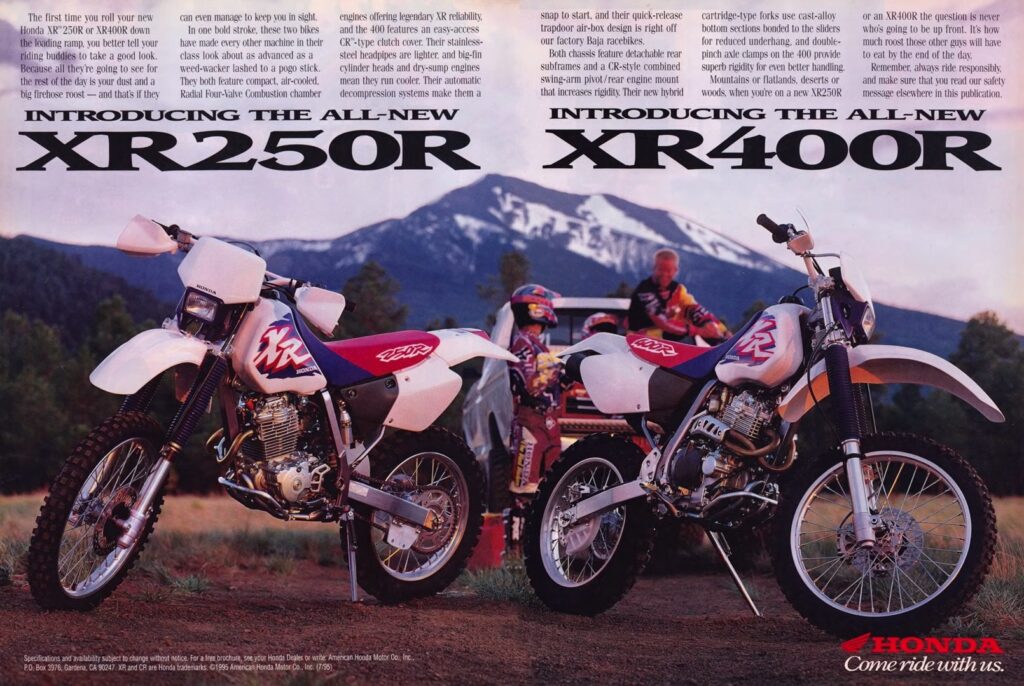

It wasn’t until a decade later that Honda launched the XR400 which built off the fame of its previous versions and by which time they had worked out several of the kinks that had shown up in the preceding decade, including overheating issues with the original wet sump and uneven fuel delivery. The XR400 continued production over the next decade with relatively minor updates limited primarily to bodywork and styling. While the Suzuki DRZ water-cooled line was certainly more competitive by the early 2000’s, the simplicity and notorious reliability of the XR range meant Honda would keep the XR400 in production through 2004 and continue to produce the RVFC engined XR650L right through to the present day!

Never famous for its performance, although upgraded versions were raced competitively, the rugged engine and simplicity ensured it as an icon of reliability and all-around fun. As Dirt Rider’s editorial staff wrote about the bike, “When I am way too many miles from nowhere, sign me up for an XR400R. I don’t care how quickly or stylishly I get to civilization, but I insist on getting there. No bike does that better than the XR400R.” Other notable Honda models that used variations of this engine design include the flat track-inspired FT500 Ascot, the XBR500, and the handsome GB500 cafe racer.

SWM and the “XR450”

With the rebirth of SWM in 2014, the company turned to its partner, Shineray Group, for a simple, robust engine for use in their “Classic” model line. As we mentioned in part one, Shineray is one of the Chinese “big four” which includes Lifan, Loncin, and Zongshen and who in recent years have built a variety of engines and components for Piaggio, Vespa, Peugot, Kymco, now-defunct Norton, BMW, Suzuki, Yamaha, Honda, and yes, Harley-Davidson.

Shineray had built engines and motorcycles under contract for Honda and had offered a version of the XR400 engine for a number of years. This 400 and variations can be found on a number of “retro-styled” motorcycles available in Europe and the US, including Mash, Herald, Genuine, Bullit, AJS, and Benelli.

SWM’s engineering, however, chose to go a step further with the engine, increasing displacement to 445cc, adding an oil cooler and more advanced oiling system, and updating the exterior with the goal of creating a middle-weight motorcycle that would still be at home at higher speeds on the freeway.

Test Engines & the “Franken450”

After establishing the quality and provenance of the 440 engine and visiting and setting up a relationship with SWM, our next step was to import a sample engine for emissions calibration testing. In order to import an uncertified, or “non-conforming” engine, we applied for an EPA testing exemption which allowed us to import a sample and begin the emissions certification process. For us, that first meant dialing in the fuel injection map to fit the weight, gearing, and intake design of the Janus 450 to meet EPA emissions standards as opposed to the similar, but slightly different Euro standards.

Our experience taking the 250 line through emissions certification had taught us just how long the process could take. In order to expedite testing, we decided to jump start the testing process prior to finalizing 450 chassis design by fitting the 450 engine into a 250 chassis. We chose a Phoenix 250 chassis for the task as it already included full suspension and would be closer to the final 450 chassis design. Even so, the conversion required extensive frame modification, including removing a significant portion of the double down tubes at the front of the frame to make room for the two exhaust headers on the 450 and redesigning the forks and swing arm to accommodate the wider wheels we had chosen for the 450.

Finally, we redesigned the air box based on our experience with the 250 as well as the SWM air box volume. In this way we were able to quickly develop a “450” chassis and running gear to begin calibration and testing on the new engine. This decision proved to be a good one as the production frame was not finalized until well after all calibration had been completed and the official testing had begun.

For more on the “Franken450”, calibration, and emissions certification, check out our video on the Halcyon 450 development:

Wiring Harness

Once we had a frame and running gear ready to house the engine, the next step in the calibration process was to get the bike running. The primary challenge here was that we needed to develop a new wiring harness that would work with the 450 engine and the electronic fuel injection system. EFI meant that we would be using an ECU (engine control unit) which is a small on-board computer that reads a variety of values including manifold absolute pressure, throttle position, engine temperature, exhaust oxygen, and engine speed, and delivers precisely the right amount of fuel via the injector for the specific riding condition.

To keep things simple, we chose to use the same Athena EFI system that SWM uses on their 440 line. Similarities between Euro and EPA emissions standards meant that this would put us in the ballpark of meeting US emissions requirements without needing to develop a new ECU map from scratch. This limited our calibration efforts to adapting the EFI system to our electrical system, air box and intake, exhaust system, and bike weight, and then ensuring that it would meet US EPA standards.

Once we had a working harness, we were able to take the test bike out on the road and start looking at the air/fuel ratio. Further calibration and a series of improvements to the wiring harness resulted in a bike with good throttle response and good enough fuel/air ratio that we knew it was time to take the bike up to S&S Cycle’s emissions test lab in Lacrosse, Wisconsin for a more exact look at our emissions.

The results from our first calibration run on their equipment were extremely positive. Our exhaust emissions were well within EPA and California ARB limits even without a catalyst. While there was room for improvement, we knew we were on the right track. Next up was the SHED test, or Sealed Housing Evaporative Determination. For this test, the motorcycle is essentially run to operating temperature and then placed in a sealed chamber which measures the evaporative emissions from the fuel tank and lines, crankcase, and oil tank. Once again, our experience with the 250 paid off and we passed with flying colors!

The EPA and CARB allow low-volume manufacturers to reduce the total duration testing miles for a Class III (279+cc) motorcycle from 30,000 km down to 15,000 km and extrapolate the wear on the emissions system. Because the emissions system does break down over time, it is necessary to build in a factor of safety. For this reason, it was important for is to include an exhaust catalyst.

By January 2021, we had the test bike prepped and ready for full EPA/CARB testing. 15,000 km take some time to put on a bike (even if S&S moved from a retired trucker to a robot putting all the miles on the bike), but emissions testing wrapped up with a pass at the beginning of May and our EPA certificate of conformity arrived 30 days later! WIth certificate in hand, we cleared our order of engines for shipment from Italy!

Power to Weight

During this calibration and certification testing, we continued to develop the new and completely redesigned full-suspension chassis for the 450. By February, the first chassis, prototype 000, was ready for initial road testing with the new engine. This took the form of a week-long trip to Tucson, Arizona and some fantastic riding. During this trip we took the bike over a variety of elevations, from snowy alpine conditions to the desert washes of the Mexican border and from the slow pace of country roads to sustained 85mph speeds up I19 from the border.

For some great footage of our Tucson trip, check out the video below!

Our initial criteria for the new “middleweight” Halcyon called for a high quality, traditional, time-tested single, easily capable of highway speeds, and with long history of reliability. Paired with a modern EFI system and our all-new chassis, this powerplant perfectly fits the bill and offers exactly the answer to what we were hoping for in the new Halcyon 450, all without losing any of the character and styling of its predecessors, the Halcyon 50 and 250. I will leave the description of the handling to ride reviews, but for me, this is the perfect development of the Halcyon concept, a vehicle that puts not only riding and the enjoyment of the road front and center, but the experience of machine with a story worth telling.

If you would like to learn even more about the Halcyon 450, check out our website, 450 production update videos, parts talks, or contact us directly!